About Coswin IoT

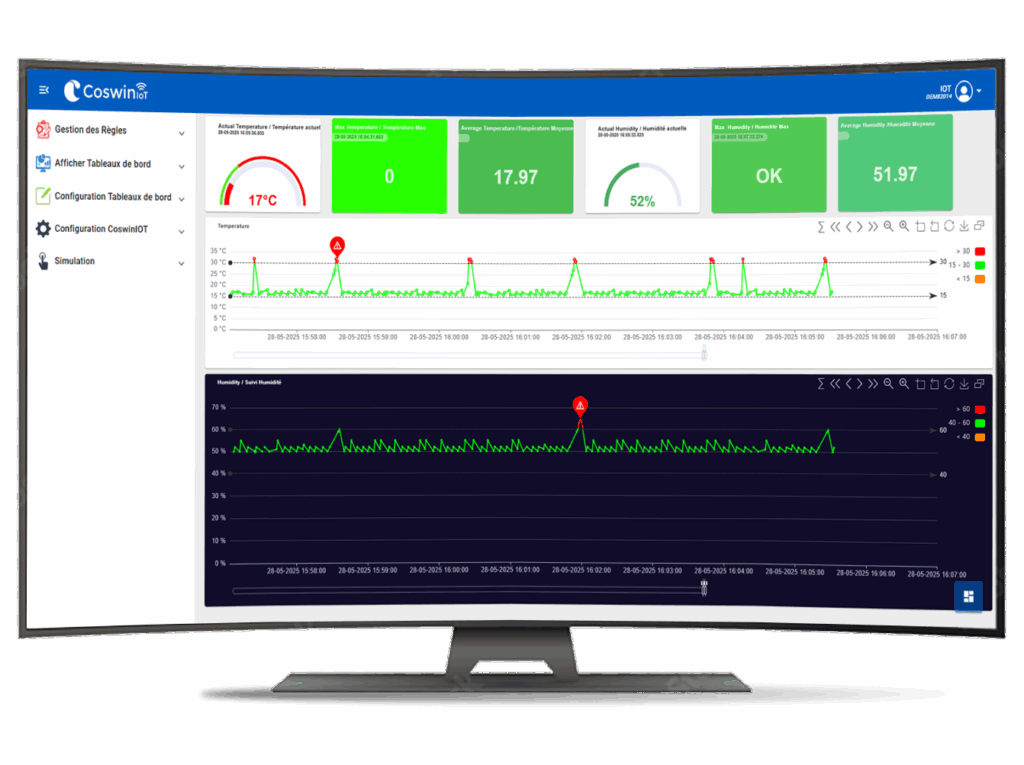

Coswin IoT collects data in the field using sensors installed on buildings and equipment. This information is processed and analysed via dashboards, which are transmitted to the CMMS through configurable rules and alerts. These directly generate the associated maintenance interventions and update equipment information in real time. Processes are automated to move from preventive maintenance to predictive maintenance. Thanks to its partnerships with recognised players in the IoT market, Siveco Group offers a comprehensive service, from sensor selection to integration with the CMMS by Maintenance Services.

The benefits of Coswin IoT

Coswin IoT enables you to:

Collect measurements, statuses, signals from equipment or sensors

Use this information to generate your indicators

Trigger maintenance actions based on measurements

Update the positions and statuses of your equipment

Update your meters to trigger your preventive measures

Optimise your predictive maintenance with machine learning

To achieve your goals

Real-time health, status and performance of an asset

Capitalising on information through condition-based maintenance

Trigger maintenance actions

Assessing the condition of the equipment fleet

Analysing readings to optimise maintenance through machine learning

Choose Coswin IoT

It is choosing a solution that allows you to:

Collect

Capitalise

Trigger

Take stock

Analyze

Collect data more easily, quickly, and securely.

Capitalising on information through condition-based maintenance.

Trigger maintenance actions: Job Request, Work Order, Condition-Based Maintenance.

Assessing the condition of the equipment fleet

Analyse readings to optimise maintenance by identifying deviant values via machine learning.

Features

Sensor identification and management

- declaration of connected sensors or machines

- Device management, gateways and association with different communication protocols

- park supervision, battery levels, connectivity, etc.

Data collection

- Data acquisition via our multi-protocol connector (MQTT, OPCUA, MODBUS TCP, etc.)

- Long-term storage and aggregation for analysis

Predictive value analysis

- Real-time indicators for viewing data/values

- Integration of a business intelligence tool for data analysis and monitoring of trends

- Machine learning to predict failures based on measurement experience

Management of maintenance control rules

- Integrated tool for creating alarm trigger rules and maintenance operations

- No development skills needed

- Ease of generalising rules to collections of measurement points

Triggering maintenance actions

- Creation of Job Requests and Work Orders

- Direct link to measurement points and conditional maintenance management

- Meter Power supply

- Real-time updates on equipment status and location

Let's talk about your CMMS project

Easier integration into your organization

Sensors, installation, communication

Siveco Group provides all services related to the implementation of your project. This includes the selection and supply of sensors, their installation, and their supervision (Device Management). We also implement communication networks for the secure transmission of information and provide unlimited data acquisition and storage.

Visualization

The Coswin IOT module allows you to create all your fleet monitoring dashboards, create rules for actions based on readings, and manage your conditional and predictive maintenance.