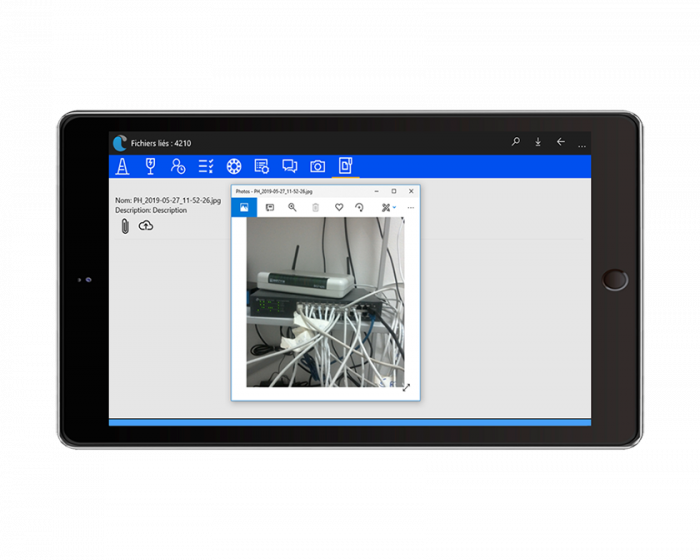

Coswin Nom@d

Coswin Nomad is a tool for maintenance on the go

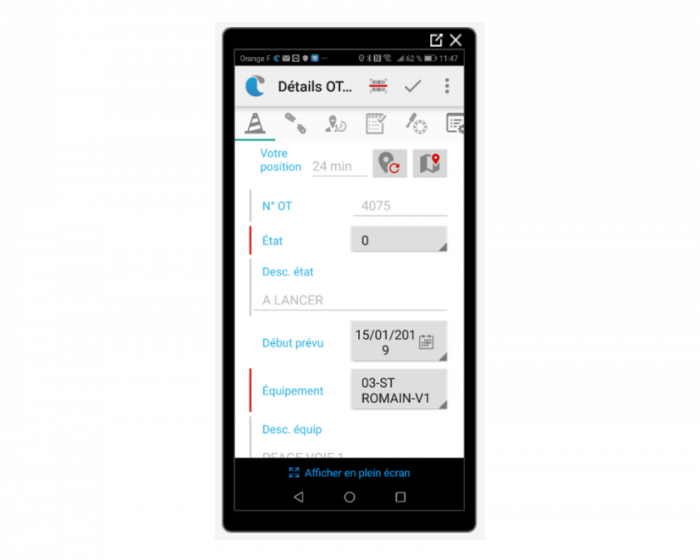

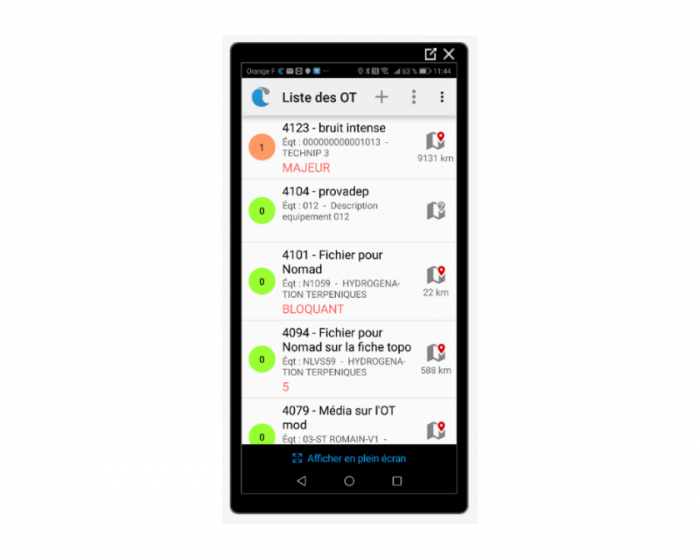

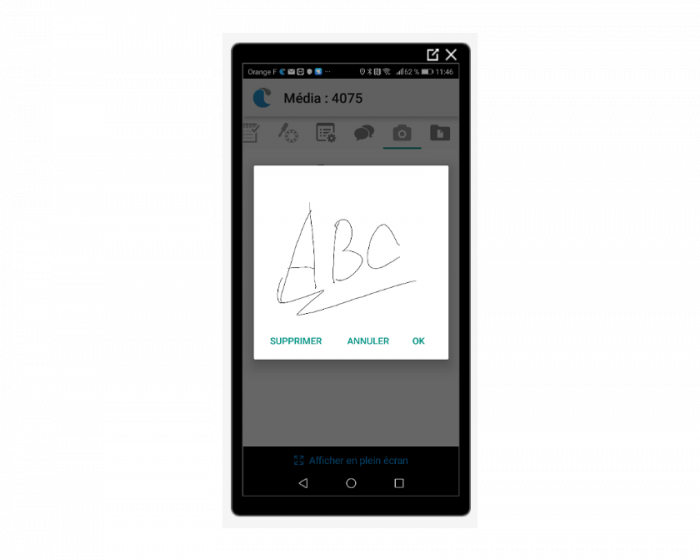

PDA, smartphones and other mobile devices have become essential working and communication tools in an environment often spread over several geographical locations. Coswin Nom@d allows remote access to the data stoked in your CMMS Coswin 8i. Your itinerant technicians can therefore receive and send data from their intervention location.

Implement this solution with us?